PRECISION CNC & MANUAL MACHINING

HIGH QUALITY MACHINING SERVICES

DMF is your number one source for quality machining services. We guarantee Precision, Reliability, and On-time delivery. Using CNC Machining we can accomplish the highest level of detail you require, holding tight tolerances for any size part you need.

CAPABILITIES:

– Threading

– External

– Internal

– Turning

– Contour Turning

– Form Turning

– Taper Turning

– Straight Turning

– Parting/Cutting

– Facing

– Boring

– Drilling

– Counter-boring

– Countersinking

– Pocketing

– Profiling

– Reaming

– Tapping

– Thread Milling

– Knurling

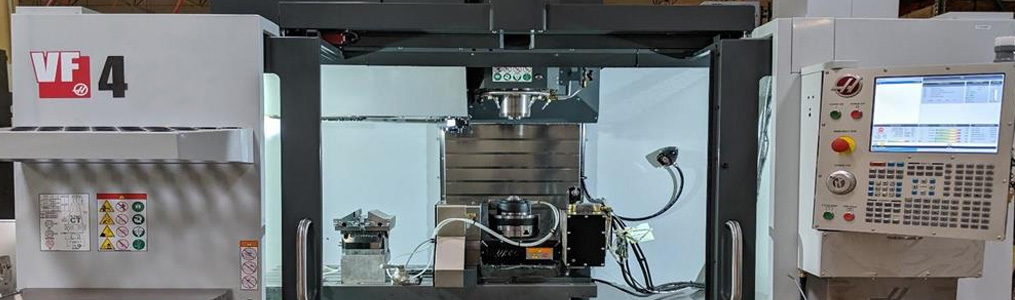

- HAAS CNC Vertical Mill VF-4

- HAAS CNC Vertical Mill VF-6

- HAAS Tool Room Mill TM-1

- Vectrax GS20V 3 Axis CNC Mill

- Kent KTM-5VK Milling Machine

- Kearney & Trecker Model K Horizontal Milling Machine

- Cincinnati Milacron Horizontal Mill No. 2MH

- Lion Engine Lathe C400TM

- Lion Gap Bed Engine Lathe 20-MS-4

- Morando PA-24 Engine Lathe

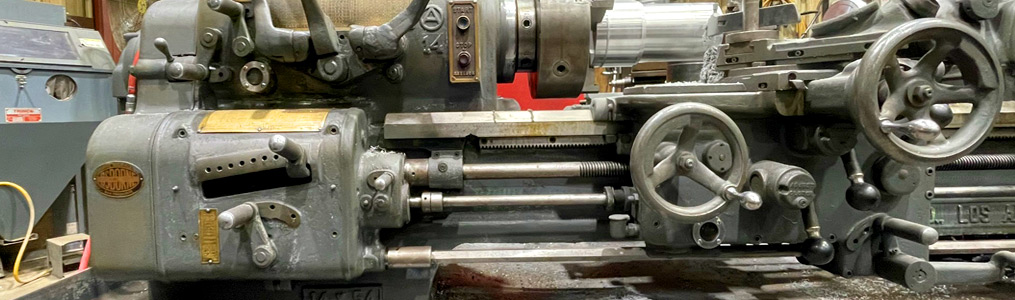

- Axelson Heavy Duty Lathe

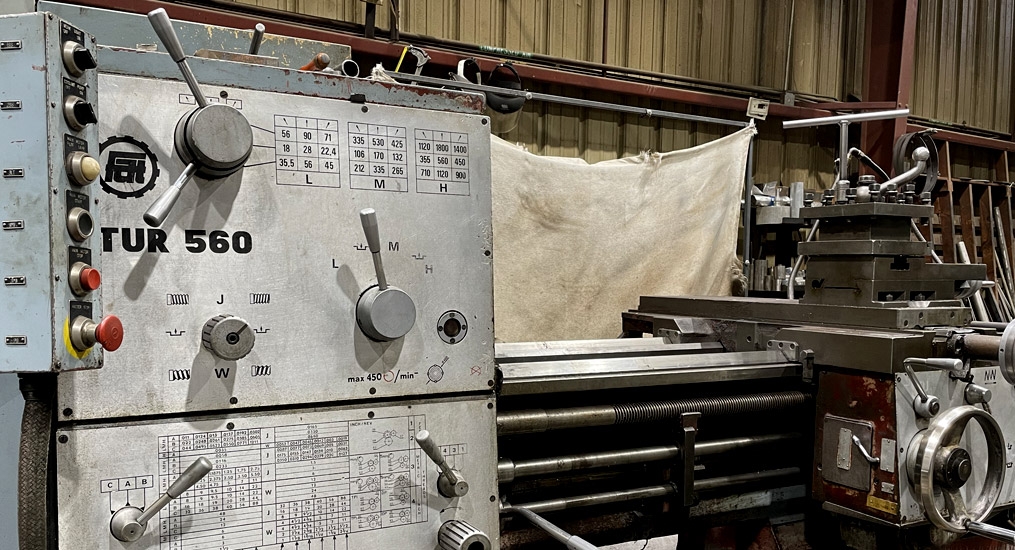

- Fabryka Automatow Tokarskich Engine Lathe TUR 560

- 1943 Betts Heavy Duty Vertical Boring and Turning Mill

HAAS VF-4 CNC Vertical Mill Specifications:

| Travels | S.A.E |

| X Axis | 50″ |

| Y Axis | 20″ |

| Z Axis | 25″ |

| Spindle Nose to Table (~ Max) | 29.2″ |

| Spindle Nose to Table (~ Min) | 4.2″ |

| Spindle | S.A.E |

| Max Rating | 30 HP |

| Max Speed | 8100 RPM |

| Max Torque | 90 ft-lbf @ 2000 RPM |

| Max Torque w/opt Gearbox | 250 ft-lbf @ 450 RPM |

| Drive System | Inline Direct-Drive |

| Table | S.A.E |

| Length | 52″ |

| Width | 18″ |

| T-Slot Width | 0.626″ in to 0.630″ |

| T-Slot Center Distance | 3.15″ |

| Number of Std T-Slots | 5 |

| Max Weight on Table (Evenly Distributed) | 3500 LB |

| Feedrates | S.A.E |

| Max Cutting | 650 IPM |

| Rapids on X | 1000 IPM |

| Rapids on Y | 1000 IPM |

| Rapids on Z | 1000 IPM |

HAAS VF-6 CNC Vertical Mill Specifications:

| Travels | S.A.E |

| X Axis | 64″ |

| Y Axis | 32″ |

| Z Axis | 30″ |

| Spindle Nose to Table (~ Max) | 34″ |

| Spindle Nose to Table (~ Min) | 4.0″ |

| Spindle | S.A.E |

| Max Rating | 30 HP |

| Max Speed | 8100 RPM |

| Max Torque | 90 ft-lbf @ 2000 RPM |

| Max Torque w/opt Gearbox | 250 ft-lbf @ 450 RPM |

| Drive System | Inline Direct-Drive |

| Table | S.A.E |

| Length | 64″ |

| Width | 28″ |

| T-Slot Width | 0.626″ in to 0.630″ |

| T-Slot Center Distance | 4.92″ |

| Number of Std T-Slots | 5 |

| Max Weight on Table (Evenly Distributed) | 4000 LB |

| Feedrates | S.A.E |

| Max Cutting | 500 IPM |

| Rapids on X | 600 IPM |

| Rapids on Y | 600 IPM |

| Rapids on Z | 600 IPM |

HAAS Tool Room Mil TM-1 Specifications:

| Travels | S.A.E |

| X Axis | 30″ |

| Y Axis | 16″ |

| Z Axis | 16″ |

| Spindle Nose to Table (~ Max) | 20″ |

| Spindle Nose to Table (~ Min) | 4″ |

| Spindle | S.A.E |

| Max Rating | 7.5 HP |

| Max Speed | 4000 RPM |

| Max Torque | 33 ft-lbf @ 1200 RPM |

| Drive System | Direct Speed, Belt Drive |

| Table | S.A.E |

| Length | 47.8″ |

| Width | 10.5″ |

| T-Slot Width | 0.626″ in to 0.630″ |

| T-Slot Center Distance | 4″ |

| Number of Std T-Slots | 3 |

| Max Weight on Table (Evenly Distributed) | 350 LB |

| Feedrates | S.A.E |

| Max Cutting | 200 IPM |

| Rapids on X | 200 IPM |

| Rapids on Y | 200 IPM |

| Rapids on Z | 200 IPM |

Vectrax GS20V 3 Axis CNC Mill Specifications:

| Controller | Centroid MSC M-15 |

| Table Size | 10″ x 54″ |

| X-Axis Table Travel | 32″ |

| Y-Axis Table Travel | 16.5″ |

| Knee Travel | 19″ |

| Ram Travel | 18″ |

| Quill Travel | 5″ |

| Spindle Type | R-8 |

| Spindle Speeds | 70-3600 RPM |

Kent KTM-5VK Milling Machine Specifications:

| Table Travel (X Axis) | 36″ |

| Saddle Travel (Y Axis) | 16″ |

| Quill Travel | 5″ |

| Knee Travel | 16″ |

| Ram Travel | 24″ |

| Throat Distance Min | 1-1/4″ |

| Throat Distance Max | 28-1/4″ |

| Table to Spindle Nose Gage Line Min | 2-1/2″ |

| Max Weight of Work Piece | 850 LBS |

Kearney & Trecker Milwaukee Model K Universal Horizontal Milling Machine Specifications:

| Long Travel | 42.00 in 1066.80 mm |

| Table Width | 18.00 in 457.20 mm |

| Table Power | 30.00 hp 22.37 kW |

| Table Length | 90.00 in 2286.00 mm |

| Spindle Power | 25.00 hp 18.64 kW |

| Spindle Speed | 13 – 1300 RPM |

| Spindle Taper | 50 NST |

| Spindle Travel | 9.00 in 228.60 mm |

| X-Axis Cross Travel | 16.00 in 406.40 mm |

| Y-Axis Vertical Travel | 22.50 in 571.50 mm |

Cincinnati Milacron Horizontal Mill No. 2MH Specifications:

| Length of Bed | 53″ |

| Axis Dimensions Approx. | Y-45″ Z- 24″ X- 52″ |

| Machine Dims | 63″ Tall 68″ Long 26″ Wide Base |

| Motor | 60 Amp 250 Volt / 3 Phase |

| Standard | 7.5 HP |

| Maximum | 15 HP |

Lion Engine Lathe Specifications:

| Swing Over Bed | 16″ |

| Swing Over Cross Slide | 9 7/8″ |

| Swing in Gap | 22″ |

| Length in Gap from 4 Jaw Chuck | 7″ |

| Distance Between Centers | 44″ |

| Spindle Nose | D1-6 |

| Spindle Bore | 2 3/32″ |

| Spindle Bearings | SKF |

| Number of Spindle Speeds | 11 |

| Range of Speeds | 54-2400 Rpm |

| Number of Threads | 34 |

| Range of Inch Threads | 60-4 Tpi |

| Range of Metric Threads | 7.5-0.5 |

| Number of Feeds | 32 |

| Range of Longitudinal Feeds | .0038-.0536″ |

| Range of Cross Feeds | .0019-.0268″ |

| Lead Screw Diameter | 1 1/4″ |

| Lead Screw Pitch | 4 TPI |

| Max. Traverse of Cross Slide | 9 5/8″ |

| Max. Traverse of Top Slide | 5″ |

| Taper Turning Work Length | 15 3/4″ |

| Maximum Taper | +/- 10 dg. |

| Tailstock Quill Diameter | 2 3/8″ |

| Tailstock Quill Taper Bore | 4 MT |

| Maximum Quill Stroke | 5 7/8″ |

| Width of Bed | 12 1/2″ |

| Ways | Hardened and Ground |

Lion Gap Bed Engine Specifications:

| Swing Over Bed | 20″ |

| Swing Over Cross Slide | 11-1/2″ |

| Swing in Gap | 26″ |

| Length in Gap from Face Plate | 9″ |

| Distance Between Centers | 60″ |

| Spindle Nose | D1-11 Camlock |

| Spindle Bore | 4-1/16″ |

| (18) Spindle Speeds | 8 to 1400 Rpm |

| Inch Threads | 4 to 120 TPI |

| Metric Threads | .5 to 7.5 |

| Longitudinal Feeds | .0019 to .9048 |

| Cross Feeds | .0007 to .4524 |

| Rapid Traverse | 148 IPM |

| Traverse of Cross Slide | 14″ |

| Traverse of Compound | 5-11/16″ |

| Taper Turning Length | 15-3/4″ |

| Maximum Taper | +/- 10 Degrees |

| Tailstock Diameter | 2-3/4″ |

| Tailstock Taper | #5 Morse |

| Quill Stroke | 8″ |

Morando PA-24 Engine Lathe Specifications:

| Swing Over Bed | 24″ |

| Swing Over Cross Slide | 16″ |

| Swing Over Gap | 32″ |

| Length of gap (in front of faceplate) | 10-1/4″ |

| Width of Bed | 15-3/4″ |

| Headstock | |

| Spindle speeds (number) | 24 |

| Spindle speeds (range) | 20-2000 Rpm |

| Hole through spindle | 3-1/2″ |

| Quick Change Gearbox | |

| Threads per inch (number) | 48 |

| Threads per inch (range) | 9/16-128 |

| Metric threads per inch (number) | 48 |

| Metric threads per inch (range) | .28-64 |

| Longitudal feeds (number) | 48 |

| Longitudal feeds (range) | .0014-.3398 |

| Cross feeds (number) | 48 |

| Cross feeds (range) | .0009-.2170 |

Axelson Heavy Duty Lathe Model 16 Specifications:

| Swing Over Bed | 18.5″ |

| Swing Over Slide | 10.75″ |

| Max Center Distance | 102″ |

| Spindle Nose | D1-6″ |

| Spindle Bore | 1-9/16″ |

| Spindle Speeds | (24) 13 to 1577 RPM |

| Tailstock Taper | #4 |

| Width of Bed | 17″ |

| Threads | (54) 1.5 to 92 TPI |

| Feed | (54) .0027 to 1.655 IPR |

Fabryka Automatow Tokarskich Engine Lathe TUR 560 Specifications:

| Maximum Swing Over Bed | 560 MM |

| Maximum Swing Over Saddle | 320 MM |

| Maximum Turning Length Between Centers | 2000 MM |

| Bed Width | 433 MM |

COMING SOON – SUMMER 2024!

1943 Betts 14′ Heavy Duty Vertical Boring and Turning Mill Specifications:

| Diameter of Table | 144″ |

| Swing Diameter | 168″ |

| Height Under Rail | 96″ |

| Speed | 0.5 – 20 RPM |

| Stroke Size | 60″ |

Equipped with:

Dual Rams

Dual Pendants

Variable Speed with Forward and Reverse Settings